In 2016, Calvalley’s Board of Directors approved institutional restructuring of Calvalley Cyprus Ltd. to bring in a consortium of new investors, Yung Holding.

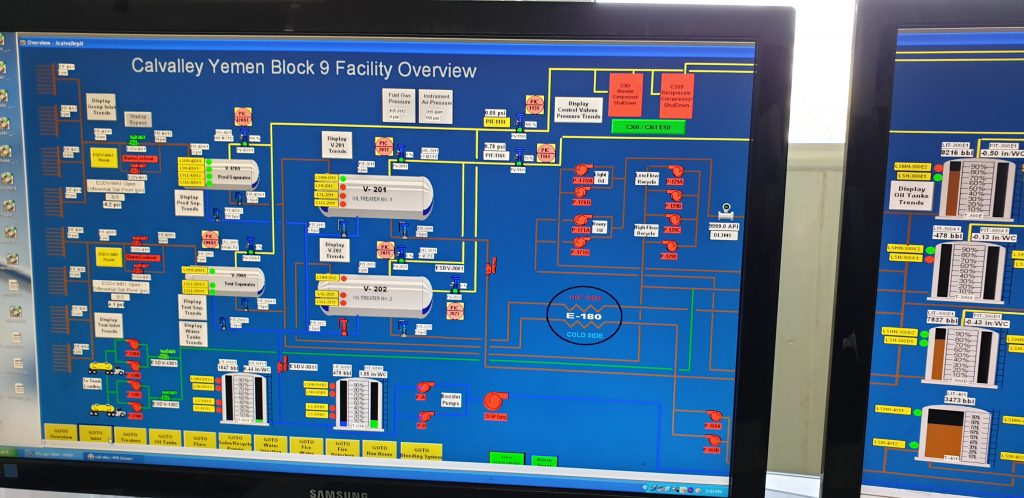

In combination with the company’s strong local relationships, this has enabled the resumption of Yemen operations, even during this difficult time, through the financing of a work programme and budget of 35-45 million USD in surface and subsurface investments, which brought the facility back into operation in 2019, with 30 wells ready to produce.